Thick Plastic Liner

FREE SHIPPING

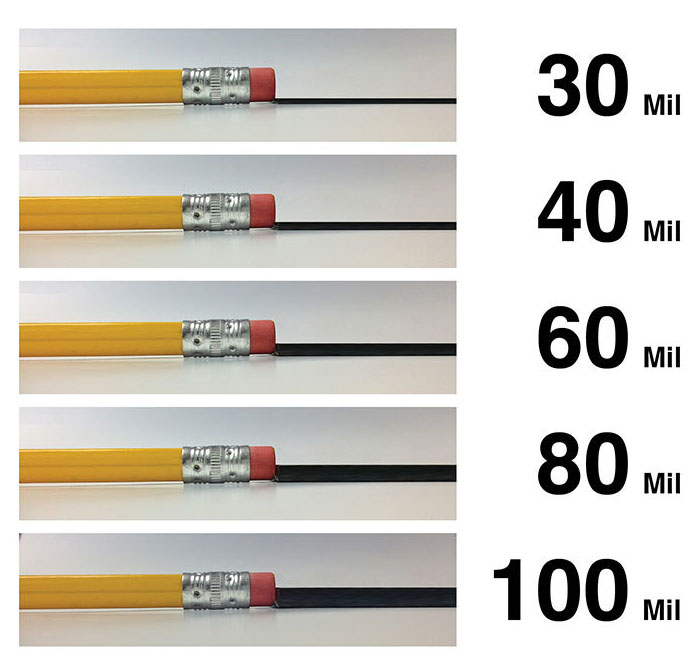

Our Thick Plastic Liner is a commercial grade HDPE plastic that provides a durable, smooth, and puncture resistant lining that can be used in a variety of applications. The plastic ranges in thickness options from 30 mil to 100 mil and in various depth options.

The thick plastic liner is non-biodegradable, waterproof, and will not rot or mildew. It has a 100 year material lifespan when not installed in direct sunlight. It can easily be cut with a standard utility knife to best fit your project needs. Made in America.

Material Thickness:

30 mil = 1/32”

40 mil = 3/64”

60 mil = 1/16”

80 mil = 5/64”

100 mil = 3/32”