Strong Plastic Sheets

FREE SHIPPING

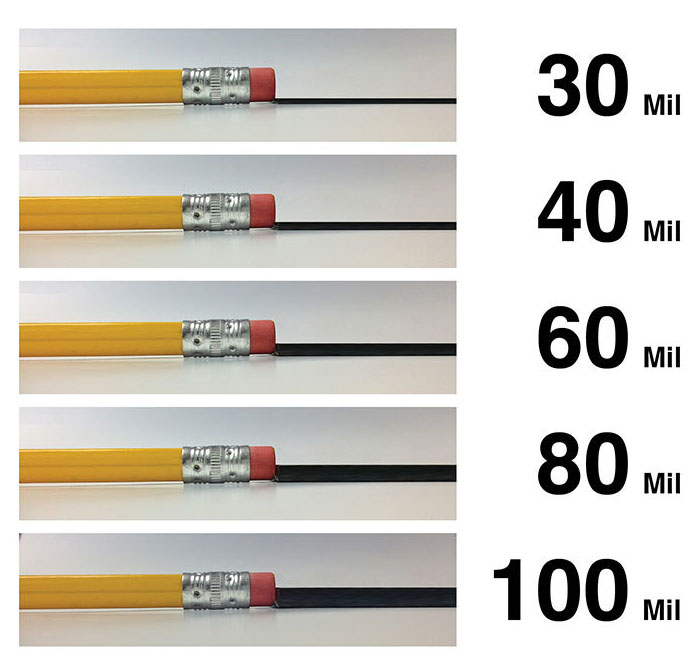

Our HDPE rolls are strong plastic sheets which are designed for both indoor and outdoor installations. The material is made from recycled polyethylene and is fully waterproof. Built-in UV inhibitors allow the plastic to resist breakdown when exposed to sunlight. The plastic sheets are available in roll widths ranging from 18” to 60”. The wide variety of widths allow for the plastic to conform to unique applications without having to cut the material down laterally. The plastic is puncture and tear resistant. Available in thickness ranging from the flexible 30 mil to the ultra strong 100 mil for heavy-duty and demanding applications. The HDPE is manufactured in the USA.