Exterior Waterproofing Membrane

FREE SHIPPING

The Exterior Waterproofing Membrane is a durable, commercial grade HDPE plastic. It can be used for commercial and residential applications where water is needed to be blocked and/or diverted from a certain area. This material is puncture resistant, waterproof and non-biodegradable with a long material lifespan of 100 years (if not in direct sunlight). It has a built in UV inhibitor to help protect the membrane from ultraviolet light.

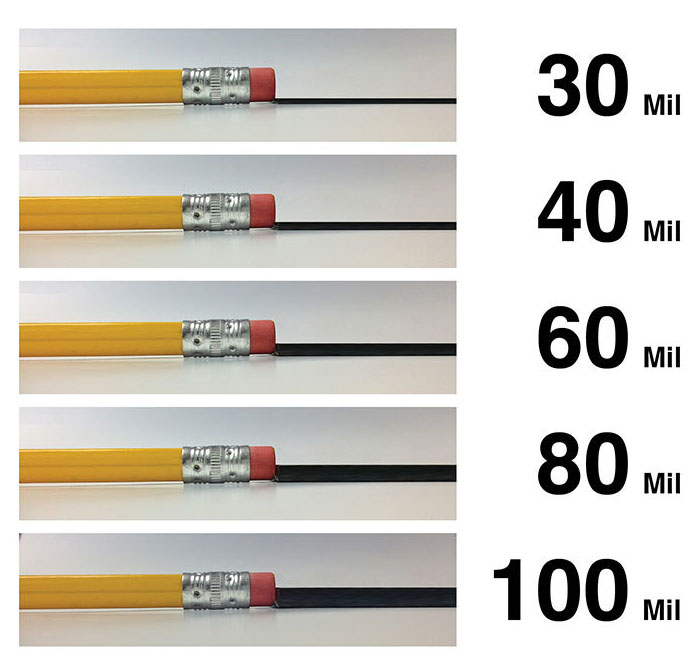

This American made product is mildew and rot resistant as well as resistant to rodent and insect damage. The Exterior Waterproofing Membrane is available in various widths and thicknesses ranging from 40 mil to 100 mil. A mil is 1,000th of an inch.