Do It Yourself Waterproof Deck Membrane

FREE SHIPPING

Our do-it-yourself waterproof deck membrane is made from high-density polyethylene (HDPE), offering a strong and waterproof solution ideal for various construction and DIY projects. This membrane is designed to resist punctures and tears while maintaining the necessary flexibility to simplify the installation process, even for those new to DIY projects.

For extensive drainage systems or larger areas, multiple sections of the membrane can be easily overlapped and securely joined using our HDPE double-sided seam tape, which is sold separately, ensuring a reliable and long-lasting waterproof barrier.

Specifications

Material: High-density polyethylene (HDPE), known for its durability and adaptability.

Width Options: Ranges from 18 inches to 48 inches.

Roll Length: Available in 100-foot lengths

Origin: Made in the USA.

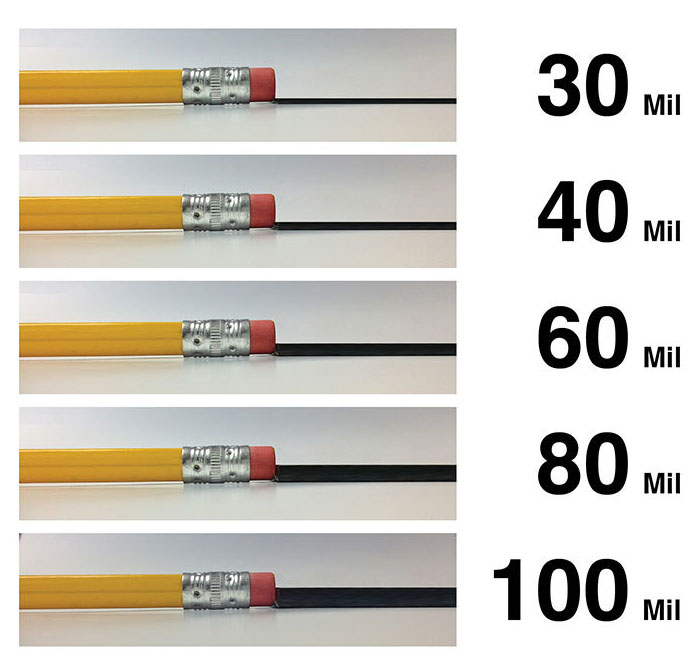

Material Thickness: 30 mil = 1/32”