Chain Trailer Liner - HDPE

FREE SHIPPING

Our Chain Trailer Liner is produced in the United States from high-density polyethylene (HDPE) and comes in rolls measuring either 100 feet or 80 feet for certain widths. With thickness options ranging from 80 mil to 100 mil and widths between 36 inches and 60 inches, this liner is versatile and can be customized to fit a variety of chain trailer sizes.

Renowned for its superior puncture and tear resistance, this liner provides durable and reliable protection. This liner boasts a longevity of over 100 years when not directly exposed to sunlight, making it an excellent investment for safeguarding your trailer interiors.

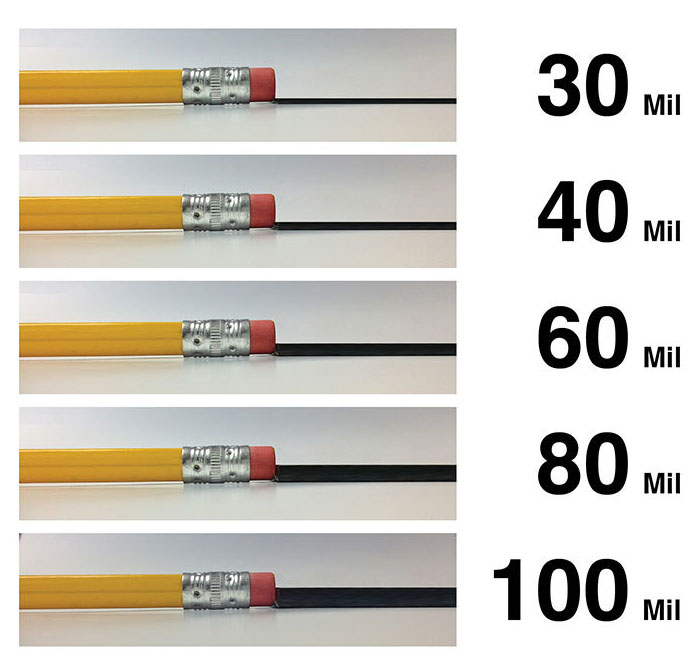

Material Thickness:

80 mil = 5/64”

100 mil = 3/32”