Invasive Plant Root Barrier

FREE SHIPPING

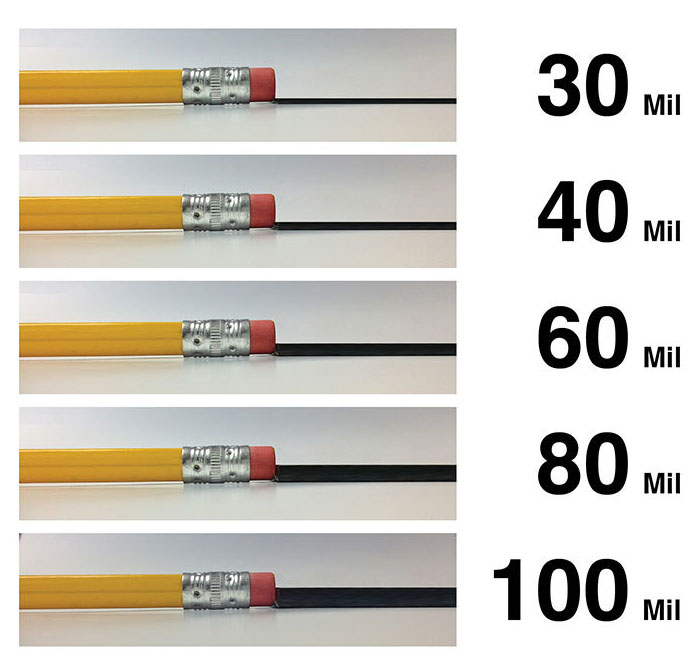

Our Invasive Plant Root Barrier composed of thick HDPE plastic that is available at various depths and thicknesses which can be best used for containing various invasive plants. These barriers are mildew and rot resistant, waterproof, and have a built in UV inhihibitor. When buried, they have an estimated lifespan of 100 years.

The barriers can be used in hot and cold climates, and are puncture and tear resistant. All of our our HDPE barriers are made in America.