Installing driveway fabric:

A Helpful Illustrated Guide

A Couple Items Before We Begin

Prior to digging into the 'How To's" of installing driveway fabric, let's start with a couple commonly asked questions by homeowners regarding fabric for driveway or paving installations.

Is it really necessary to put fabric under my gravel driveway?

Yes, if you want your driveway to last.

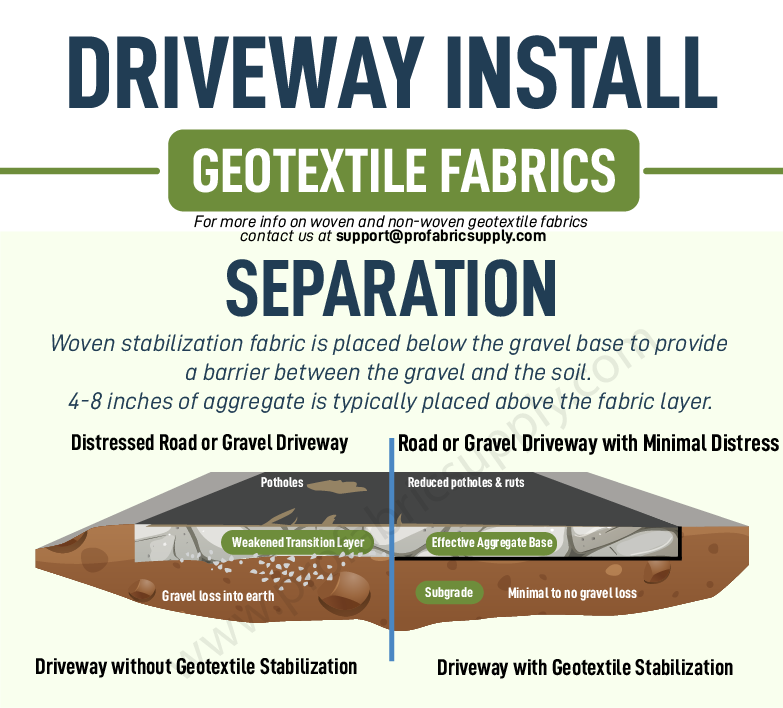

Having geotextile fabric under your gravel driveway will prevent you from continually needing to add more aggregate base to your road since the rock will drop into the subgrade layer. A separation and stabilization fabric layer below the driveway reduces the amount of gravel needed during the initial installation and required maintenance in the future.

How does driveway fabric work?

Driveway fabric works by providing a separation layer between the driveway gravel and the earth below. Due to its high tensile strength the fabric acts as a stabilizing layer and reduces the amount of rock required by up to 30% which results in a reduction of labor and overall cost.

This post will go over the classes grades of woven fabric along with the following steps of the installation process:

- Site Preparation

- Fabric Installation

- Secure/Pin with Staples

- Adding Base Gravel

Additionally we'll address the most frequently asked questions on installing geotextile fabric for driveways and what products to use. At the end of the page you can find a few additional resources if your interested in diving into some further technical reading.

Classes of Woven Fabrics

There are generally 3 classes of woven geotextile fabric that is used for both residential and commercial road applications these grades range from standard grade, then progress to intermediate grade and finally to the heavy duty grade class. Each class progressively increases strength and offers different levels of permeability.

Standard Grade

Characteristics: A single sheet with very low to non-permeability. Standard grade does not drain as well as higher grade fabrics

Ideal use: Great for Separating soils or aggregates. Commonly used in residential applications. Best placed in dry areas with relatively low surface water.

Intermediate Grade

Characteristics: Monofilament weave with higher tensile strength fabric than standard grade, but allows dissipation of water. There is an inverse correlation to the strength and flow-through rate, with higher strength comes reduced flow rate.

Ideal use: Can be used for all 5 of the functions of a geotextile fabric: separation, stabilization, filtration, drainage, & reinforcement. Great for any residential or commercial driveway application.

Heavy Duty Grade

Characteristics: Woven with both rectangular and round fibers for a "3D weave." This has the highest strength of all the woven fabrics with none of the drawbacks. Heavy-duty grade enables water to flow through extremely well.

Ideal use: Can be used for all 5 of the functions of a geotextile fabric: separation, stabilization, filtration, drainage, & reinforcement. Great for any residential or commercial driveway application. This class of fabric is typically installed in commercial or industrial applications.

Steps for installing Driveway Fabric

Step 1. Site Preparation

Prepare the site and remove all vegetation from the area. This could include shrubs, grass or other brush that might be in way of the path.

The surface of the subgrade soil should be both smooth and level, grade the entire area to remove any high spots or depressions in the ground. A uniformly flat dirt path is critical as it ensures a good foundation from which to lay down the fabric and build your aggregate base on.

If you have any wet or damp subgrade please consult your project engineer as more may need to be done to ensure a stable base layer level.

Step 2. Fabric Installation

Install the woven geotextile fabric roll in the same direction as indicated on the project plans. By orienting in the correct direction, it will ensure a long life of the pathway and the product will perform to the its full design strength.

Typical roll sizing for woven fabrics range from 12.5’-17.5’ wide. It’s good to keep this in mind when ordering as it will typically be delivered by a less than truckload (LTL) freight truck.

Step 3. Secure with Staples

Once all the fabric is on the ground, you’ll need to secure it so that it does not move. Use standard 6” landscape staples or pins to secure the fabric to the ground and prevent it from shifting or moving over time.

Using approximately 1 staple every square yard of material, or if you’re just stapling the sides and center it would be 1 staple for every 3 linear feet.

Step 4. Add/Spread the Base Material

Finally, add the base material on top of the geotextile fabric. If you’re adding aggregate rock to your driveway then its recommended to have a minimum of 8-12 inches depth of rock on top of the fabric and potentially much more depending on the composition/stability of your subgrade and what is indicated on the project plan.

You are able to drive on the fabric before the base is on top in order to dump the crushed rock, however go slow, less than 10 mph and be careful not to stop abruptly or make any sharp turns as that may damage the fabric material.

Once you have laid the stable base then its time to compact the gravel down using a compacting tool or

appropriate loader vehicle with the correct attachment.

Other Frequently Asked Questions:

The following are more commonly asked things I respond to when addressing the topic of driveway fabric installation.

What is the best kind of fabric for driveways?

A woven geotextile fabric that has a higher grab/tensile strength is a great choice for driveway or paving fabric as it will withstand the weight of heavy vehicles over time. The grade of woven fabric will largely depend on your area and the drainage situation at your site. Standard grade fabric is used more in residential applications whereas civil/commercial applications often call for Intermediate or heavy duty grade.

What is the best base material for a driveway?

The ideal aggregate base material for a driveway is crushed rock or “minus” as it will compact down nicely creating a solid path to drive over. Another benefit to crushed rock is that it is easy to install and quite inexpensive compared to permeable pavers, concrete, or asphalt.

How much does driveway fabric cost?

Driveway fabric or woven geotextile fabric ranges in cost from $200 to $3,800/roll depending on the roll size and technical rating and strength.

Where can I buy driveway fabric?

Driveway fabric can be purchased from a geotextile distributor both regionally via a local warehouse or online. ProFabric Supply (www.profabricsupply.com) offers a full selection of driveway fabric in different roll sizes to suit any project.

What do I do if I damaged the fabric?

Don’t worry if you’ve punctured through a spot in the geotextile fabric, it can be repaired by adding on another layer of fabric over the damaged portion. Be sure to overlap the fabric at least 36” in every direction around the damaged section.

Conclusion

For driveway and road applications its best practice to use a woven geotextile fabric to ensure the longevity and life of your roadway. By separating the subgrade and base layers you can reduce rutting, and potholes and increase surface drainage.

For questions regarding custom project quotes, or to speak with a geotextile product specialist contact us at

(800) 520-7731, or email us your questions at support@profabricsupply.com